Researchers find a way to reclaim materials from epoxy resins and composites

For the first time, a team of researchers, including those from the University of Tokyo, developed a method to efficiently reclaim materials from a range of epoxy products for reuse by using a novel solid catalyst.

Posted On 15 Feb 2025

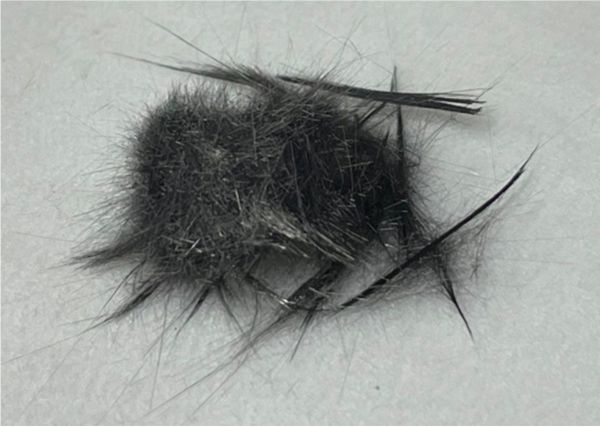

Recovered carbon fibers. This might look like something you’d see on the floor of a barber’s shop, but it’s actually a clump of reclaimed carbon fibers. ©2025 Jin et al. CC-BY-ND

Epoxy resins are coatings and adhesives used in a broad range of familiar applications, such as construction, engineering, and manufacturing. However, they often present a challenge to recycle or dispose of responsibly. For the first time, a team of researchers, including those from the University of Tokyo, developed a method to efficiently reclaim materials from a range of epoxy products for reuse by using a novel solid catalyst.

There’s a high chance you are surrounded by epoxy compounds as you read this. They are used in electronic devices due to their insulating properties; clothing such as shoes due to their binding properties and physical robustness; building construction for the same reason; and even in aircraft bodies and wind turbine blades for their ability to contain strong materials such as carbon fibres or glass fibres. It’s hard to overstate the importance of epoxy products in the modern world. But for all their uses, they inevitably have a downside: Epoxy compounds are essentially plastics and prove difficult to deal with after their use or at the end of the life of an epoxy-containing product.

“For example, to decompose fibre-reinforced plastics, perhaps used in aircraft parts, you’d need high temperatures over 500 degrees Celsius, or strong acid or base conditions. These things have an energy cost, and the harsh conditions can damage the fibres and things you might be trying to recover,” said Associate Professor Xiongjie Jin at the University of Tokyo. “To deal with this problem, a relatively new process called catalytic hydrogenolysis shows promise, but existing catalysts for this are not reusable as they dissolve in the solvent in which the epoxy decomposition takes place. So, we created a new solid catalyst which is easily recoverable and reusable.”

Jin and Professor Kyoko Nozaki, both from the Department of Chemistry and Biotechnology, and their team developed an efficient and robust catalyst to decompose epoxy compounds into carbon fibres, glass fibres and phenolic compounds, which are important raw materials in the chemical industry. The catalyst is referred to as bimetallic as it uses two metals, nickel and palladium, which are supported on cerium oxide and work together to mediate reactions between epoxy resins and hydrogen gas. Though the reaction temperature needs to be at around 180 degrees Celsius, the energy requirements are far lower than those needed to create 500-degree conditions, and the lower temperatures mean recovered materials can be reused.

Realted Content

Siemens unveils breakthrough innovations in ind ...

Siemens showcased its vision for the ...

Read More

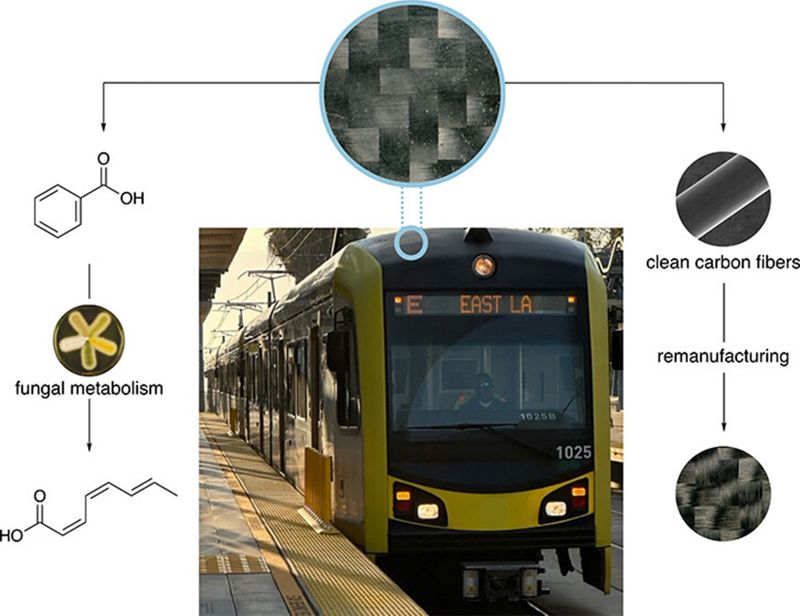

Researchers develop a biotechnological process ...

Researchers have developed a chemical ...

Read More