Mikrosam delivers upgradeable filament winding system to Epsilon Composite, Turkey

This system is designed for wet winding over cylindrical mandrels and liners, provisioned to wind mandrels with towpreg material in the future

Posted On 03 Mar 2025

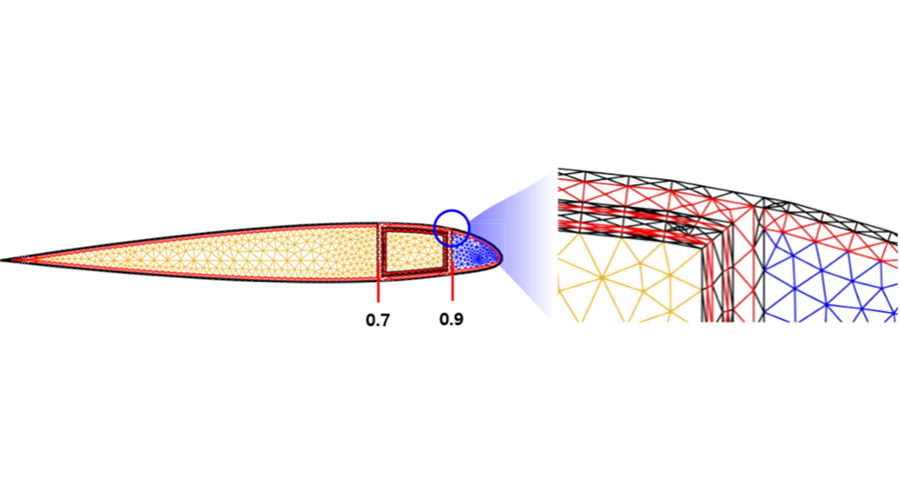

Mikrosam, a leader in composite machinery manufacturing, is proud to announce the successful delivery of a high-performance, upgradeable filament winding system to Epsilon Composite, Turkey. This system is designed for wet winding over cylindrical mandrels and liners, provisioned to wind mandrels with towpreg material in the future. It supports Epsilon’s mission to advance composite tank production for high-performance applications, customizable to customer needs, in many industries, including the automotive industry for hydrogen systems for modern and heavy-duty vehicles (trucks), where large storage capacities are required.

This project exemplifies Mikrosam’s unmatched ability to deliver fully integrated, high-performance composite manufacturing systems. The delivered solution includes:

- Filament Winding Machine: A double-spindle system with an overhead beam configuration, enabling high-speed, precision winding of carbon and glass fibers. It supports mandrel diameters up to 700 mm and lengths up to 2,950 mm.

- Impregnation Resin Bath System: It is equipped with programmable doctor blade for precise resin pick-up settings, allowing each fiber tape, routed to different spindles, to have individual and programmable resin pick-up adjustments, which is crucial for ensuring consistent and optimal process quality.

- Electronic Fiber Creel and Tension System: A robust, enclosed creel with electronic tension control for smooth, precise fiber unwinding

- WindingExpert Software: Mikrosam’s proprietary software provides advanced offline programming, 3D simulation, and quality assurance, streamlining production planning and execution.

- Stationary Curing Oven: Custom-designed to cure wound cylinders with precise temperature control, ensuring material integrity and part consistency.

Engineered for High-Performance Applications

Mikrosam’s filament winding machine is engineered to meet the exacting standards of modern composite manufacturing. This machine plays a pivotal role in Epsilon’s upcoming R&D initiatives, paving the way for breakthroughs in composite manufacturing and clean energy solutions. Key features include:

High-Speed Operation: Four-axis control for synchronized movements, supporting geodesic and non-geodesic winding patterns with unmatched accuracy. Modular and upgradeable machine system, which includes the possibility of installing a 5th axis in the future.

Customizable and Future-Proof Design: Ready for towpreg winding and advanced automation upgrades.

Integrated Quality Control: A built-in Quality Control System (QCS) tracks critical production parameters such as fiber tension, resin temperature, and winding speed for traceability and consistency.

“Epsilon Composite is investing in state-of-the-art filament winding systems to revolutionize the production of hydrogen storage tanks and aerostructure components. Mikrosam’s advanced filament winding machine empowers us to develop cutting-edge hydrogen storage systems designed to meet the rigorous demands of modern vehicles. Beyond storage, this technology enables the manufacturing of critical aerostructure parts, driving innovation, efficiency, and sustainability across our operations”– Epsilon Team.

The system seamlessly integrates with Epsilon’s proprietary K1 technology to produce lightweight, large-diameter composite parts with exceptional stiffness.

Realted Content

Siemens unveils breakthrough innovations in ind ...

Siemens showcased its vision for the ...

Read More

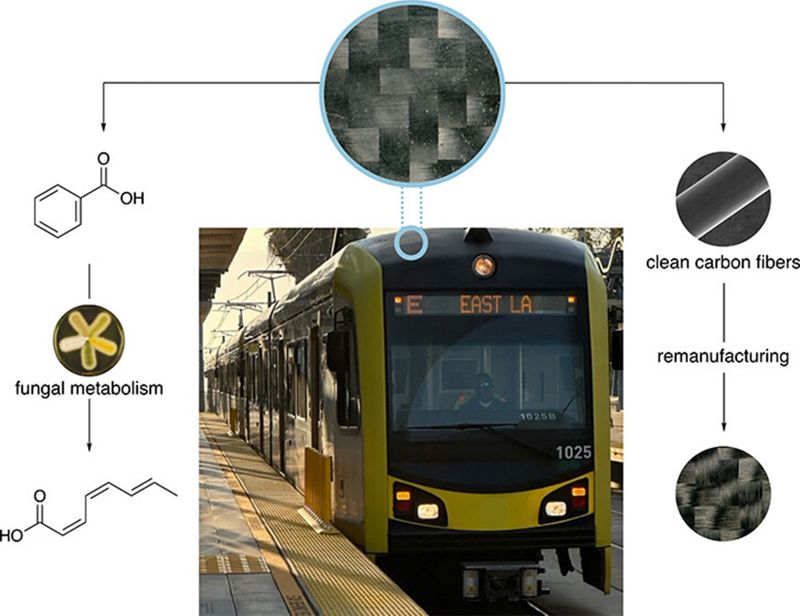

Researchers develop a biotechnological process ...

Researchers have developed a chemical ...

Read More