Creating Value- Need for Right Tools, Skill Sets & Automation

In many sectors in the field of composites, the product manufacturers play a crucial role in the growth of the sector and they are in the middle of the value chain

Posted On 14 Feb 2025

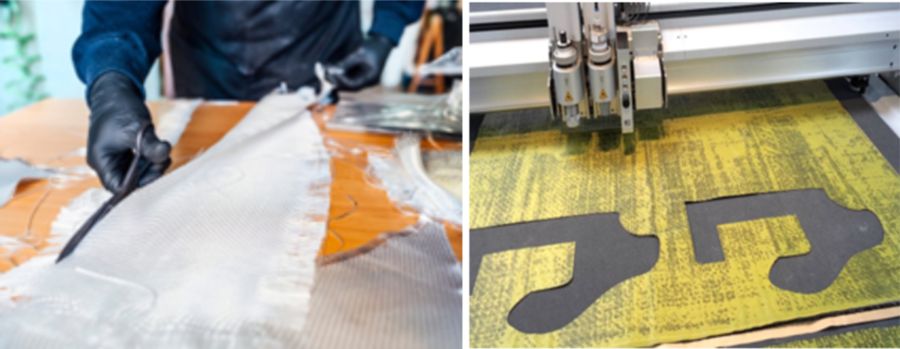

Fabric cutting manual and using cutting machine

In many sectors in the field of composites, the product manufacturers play a crucial role in the growth of the sector and they are in the middle of the value chain, on one end they have to get the right raw materials and convert it efficiently and in the other end, they have to deliver it to the end-user meeting their specifications and requirements. In meeting the end-user requirements and get them satisfied in terms of cost, delivery, and performance, it is important to adopt right tools to improve efficiency and by doing so,

-It can save lot of time,

-It can help in ease of operation and result in efficient utilization of man power and resources

-It can help to improve the quality of the product- Quality-in general, It does not cost but pays off

-It avoids reworking and saves cost

-It provides smooth operation in meeting the deadlines, delivery and ultimately the Customer Satisfaction, Customer retention and overall growth.

Thus, to achieve efficiency and consistency, apart from tools and accessories, adoption to automation is another step forward. When we say automation, very often it comes to our mind is that of reducing man power, but our focus should be putting the man power for its best utilization and increasing the productivity.

In the process of converting from the raw materials to the finished composites products and in advanced materials in general, there will be number of individual processes and stages that they have to execute and companies can focus on reducing the total number of steps, even by one or two steps and it will have a cumulative effect and may result in savings in a long run.

For example, in the case of composites manufacturing, creating a preform of dry reinforcement, a shape of the product that is going to be manufactured, may be helpful for reducing the setting up time in composites manufacturing. In the current scenario, in most cases, a small manufacturing firm putting up a preforming facility may not be viable option, unless there is a huge of volume requirements of same product. These kind of preform manufacturing, a kind of value addition role that can be played by the traders or a new value a creator who can join the value chain. It has another advantage that this type of value creator, or the trader can find a new use for the cut wastes and it can be used as a resource for one of his other customers.

Trained manpower with right skill sets are important for achieving efficiency thereby it may help in faster delivery, reduced defects and rejections. A trained skilled technician will be an asset to any manufacturing activity including operation and maintenance of equipment/ machinery and an any anomality observed early can avoid costly break down and associated downtime which will result in huge cost for maintaining productivity as well as costly replacements. Even the best materials if not processed properly it will be a loss and it will add up to the cost.

Let us begin with an approach of putting a one-step-up in the Technology ladder.

Realted Content

Siemens unveils breakthrough innovations in ind ...

Siemens showcased its vision for the ...

Read More

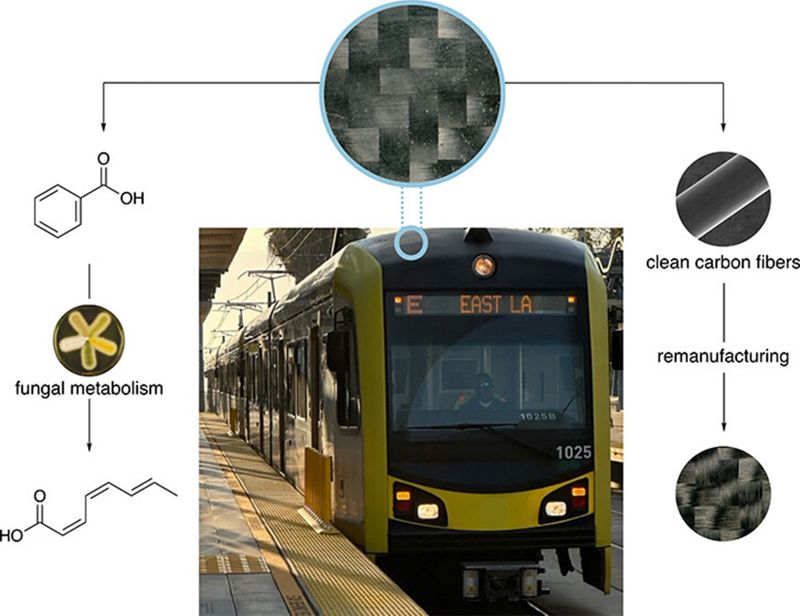

Researchers develop a biotechnological process ...

Researchers have developed a chemical ...

Read More