Surfboards made from decommissioned wind turbine blades

ACCIONA joins forces with pro surfer Josh Kerr to produce a high-performance prototype surfboard made from a retired wind turbine blade

Posted On 06 Mar 2025

ACCIONA (Australia), a leader in renewable energy and sustainable infrastructure, has partnered with professional surfer Josh Kerr and his surfboard brand Draft Surf, to create the world’s first surfboards made from a retired wind turbine blade.

Crafted from a decommissioned blade from ACCIONA’s Waubra wind farm in Victoria, an initial range of ten prototype boards was produced as part of ACCIONA’s Turbine Made initiative. Launched in February, Turbine Made is Australia’s first initiative dedicated to exploring innovative ways to transform decommissioned wind turbine blades into new materials and products. It represents the next step in ACCIONA's efforts to advance circular economy in the renewable energy sector in Australia.

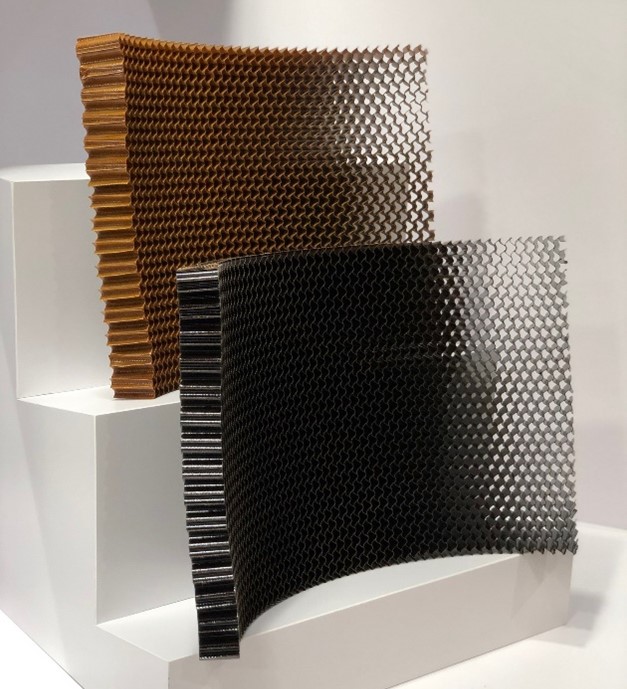

The surfboards, hand crafted on the Gold Coast, feature repurposed turbine blade strips built into the deck for strength and flex control. The fins of the board, made from recycled fiberglass, provide stability, drive and speed and the outer shell is further strengthened by incorporating recycled turbine blade particulate into the fibreglassing process.

Josh Kerr, Australian professional surfer and founder of Draft Surf said: “When ACCIONA approached us about being part of the solution and working together to create these surfboards, we jumped at the opportunity. At its core, our brand is about enabling the best surfing experience with quality products, in a sustainable way - which aligns with ACCIONA’s vision for Turbine Made”.

ACCIONA Energia’s Global Sustainability Director Mariola Domenech, said: “We know that in the next 5 to 10 years countries like Australia will have a large volume of decommissioned wind turbine blades, so we’re acting now to explore new ways to recycle and reuse the material they are built from.

“The creation of a surfboard prototype, developed locally, is an example of how we're reimagining the materials from decommissioned turbine blades and pushing the envelope of innovation when it comes to the circular economy.”

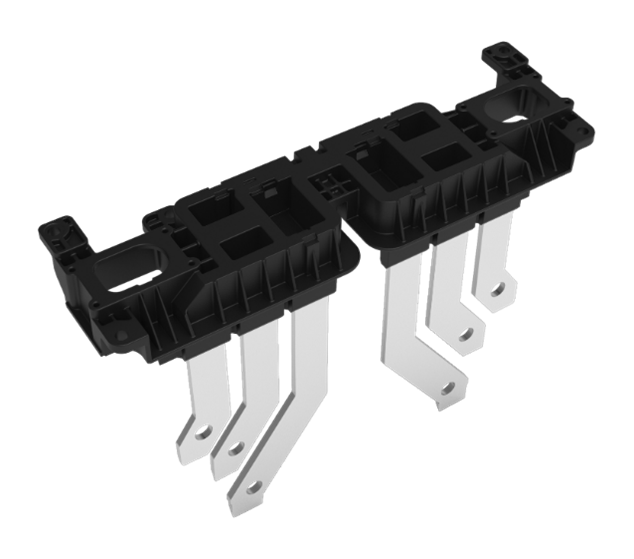

The Turbine Made initiative builds on ACCIONA's previous work to repurpose decommissioned wind turbine blades. This includes a collaboration with European fashion brand El Ganso, to create sneakers featuring recycled blade material in their soles and integrating recycled blade materials into the torsion beams of solar trackers at a solar plant in Extremadura, Spain.

ACCIONA is also advancing in end-of-life turbine recycling through the development of a blade recycling plant in Navarra, Spain, which is set to become operational in 2026, creating 100 jobs and a processing capacity of 6,000 tonnes of material per year.

“Sustainability isn’t just about reducing waste—it’s about product stewardship, ensuring that what we build today doesn’t become tomorrow’s environmental challenge,” said Ms Domenech.

“By working with Australian manufacturers, designers, and innovators, we can encourage the creation of practical, high-performance applications that benefit both industry and the environment."

Realted Content

BASF launches innovative PPA for electric vehic ...

BASF announced that its newly develop ...

Read More