Sicomin collaborates with MADskis to maximise performance and sustainability

Sicomin announces partnership with MADskis incorporate bio-based epoxy resin into its high-performance ski production.

Posted On 15 Feb 2025

Sicomin, a pioneer in bio-based epoxy systems, announces its partnership with MADskis, the Swiss company renowned for crafting handmade skis with a commitment to innovation and sustainability. MADskis will now incorporate GreenPoxy® 56 resin, known for its industry-leading bio-content of 51%, into its high-performance ski production.

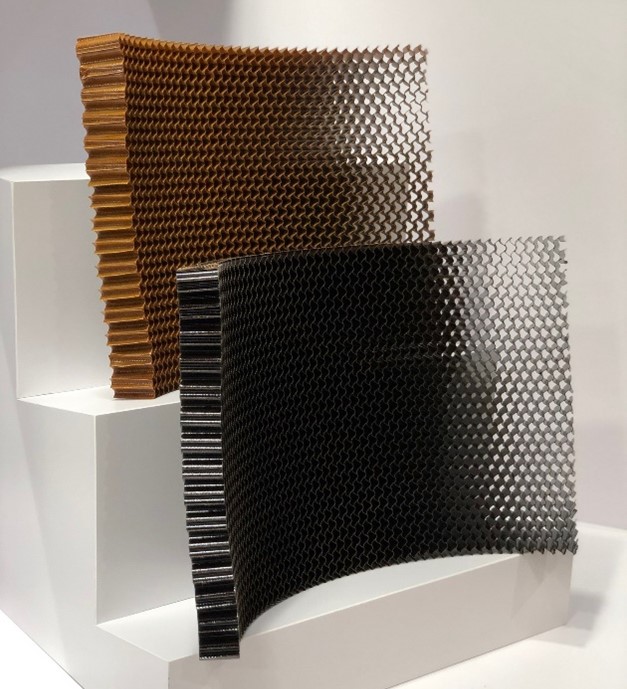

The Sicomin and MADskis collaboration sets a new standard in winter sports manufacturing, showcasing maximum sustainability, uncompromised performance on the slopes and improved working conditions. With the highest bio-content available, GreenPoxy 56 delivers great mechanical performance as well as meeting MADskis challenging production and environmental requirements. It also ensures a cleaner, safer production environment for the MAD production team, as they hand laminate wooden top sheets, natural fibres and European wood cores in their boutique workshop.

MADskis was co-founded by Aurélien Ducroz, a celebrated professional skier and Class40 ocean racing world champion. Ducroz’s Class40 yacht was constructed using Sicomin GreenPoxy resins and flax fibers, highlighting the resin’s durability. Ducroz will now apply the similar processing techniques and materials at MAD, creating cutting-edge, lower impact skis. MAD’s revolutionary UNDO-REDO process uses bio-based resins and natural wooden topsheets to enable skiers to repair or replace the upper layers of their skis. This innovation significantly extends the lifespan of the skis, reducing waste and promoting eco-responsibility.

The Sicomin and MADskis collaboration sets a new standard in winter sports manufacturing, showcasing maximum sustainability, uncompromised performance on the slopes and improved working conditions. With the highest bio-content available, GreenPoxy 56 delivers great mechanical performance as well as meeting MADskis challenging production and environmental requirements. It also ensures a cleaner, safer production environment for the MAD production team, as they hand laminate wooden top sheets, natural fibres and European wood cores in their boutique workshop.

GreenPoxy 56 is a high-performance resin system formulated with 51% of its carbon content from biobased sources. Its unique formulation and low viscosity mean it quickly and efficiently wets out reinforcements under hand lamination, vacuum bag or press consolidation processes. A range of different reactivity hardeners are available to suit the varied laminating and bonding challenges of custom ski manufacturing.

Realted Content

BASF launches innovative PPA for electric vehic ...

BASF announced that its newly develop ...

Read More