RATH starts production of oxide ceramic continuous fibre in K99 and M75 qualities

This makes RATH the first European supplier to offer a solution for manufacturers of composite materials and manufacturers and processors of temperature-resistant fabrics

Posted On 19 Feb 2025

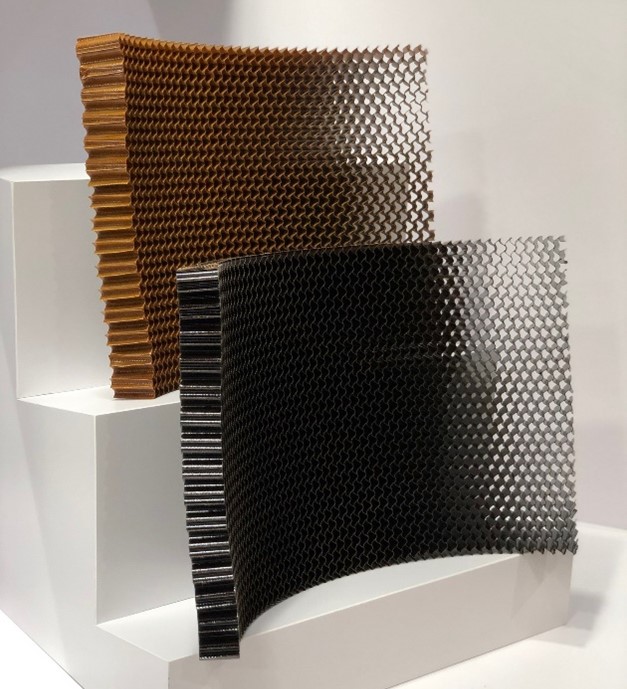

Recently, the international refractory manufacturer started production of the innovative ALTRA FLEX® oxide ceramic continuous fibre in K99 and M75 qualities.

RATH has been developing oxide ceramic continuous fibre for several years. The production plant for the manufacture of the ALTRA FLEX® oxide ceramic continuous fiber in K99 and M75 qualities was recently commissioned at the RATH Mönchengladbach site (Germany). This makes RATH the first European supplier to offer a solution for manufacturers of composite materials and manufacturers and processors of temperature-resistant fabrics. The new production plant will initially produce up to 10 tons of fibre per year.

“Drawing on 35 years of experience in the development and production of high-temperature ceramic fiber, RATH is always looking for innovative ways to develop new, pioneering product solutions for industry. The addition of ALTRA FLEX® oxidic ceramic continuous fiber in two grades has enabled us to once again expand our broad portfolio of pioneering solutions”, says Christopher Kluthe, Senior R&D Manager, RATH. “ALTRA FLEX® is unsurpassed in the industry and maintains both strength and flexibility up to 1200 oC”, adds Christopher Kluthe. Other advantages include high thermal shock resistance, excellent dimensional stability and low thermal conductivity.

Ideal for a wide range of applications, from 3D printing to composites

The properties, especially the retention of flexibility in extreme temperature ranges, open up many possibilities. The roving is ideal for fabrics, 3D printing, composites, weaving, braiding and more. These product properties make ALTRA FLEX® a future-oriented material in many industries and fields of application.

ALTRA FLEX®: important raw material for the production of oxide ceramic matrix composites

Oxide ceramic continuous fibre is widely used, especially as reinforcing fibres in various matrices (CMC, MMC). Due to its high tensile strength and stiffness as well as its excellent chemical and thermal resistance, continuous fibre can, for example, provide ceramic matrices with quasi-ductile, damage-tolerant fracture behaviour. "This continuous fibre is an important raw material for the production of oxide ceramic matrix composites”, concludes Christopher Kluthe.

An annual production of up to 10 tons of ALTRA FLEX® oxide ceramic continuous fibre is planned

The fibre, produced using the sol-gel process with a dry spinning technique, has a mullite or corundum microstructure after its thermal treatment. To date, RATH has developed the corundum fibre K99 (with a tensile strength of up to 3,000 MPa and an E-modulus of over 350 GPa) and the mullite fibre M75 (with a tensile strength of up to 1,500 MPa and a modulus of elasticity of over 200 GPa).Other qualities, especially those with higher creep resistance, are already in development. Initially, up to 10 tons of ALTRA FLEX® oxide ceramic continuous fiber are to be produced annually in the new production plant in Mönchengladbach.

ALTRA FLEX® is a product of RATH Research and Development and was created as part of the HORIZON EUROPE project InVECOF (Innovative Value Chains for European Ceramic Oxide Fibers).

Realted Content

BASF launches innovative PPA for electric vehic ...

BASF announced that its newly develop ...

Read More