James Cropper launches SURFACETEC material

SURFACETEC streamlines composite manufacturing by enhancing surface quality, optimising resin flow, imparting functionality and reducing process complexity

Posted On 11 Mar 2025

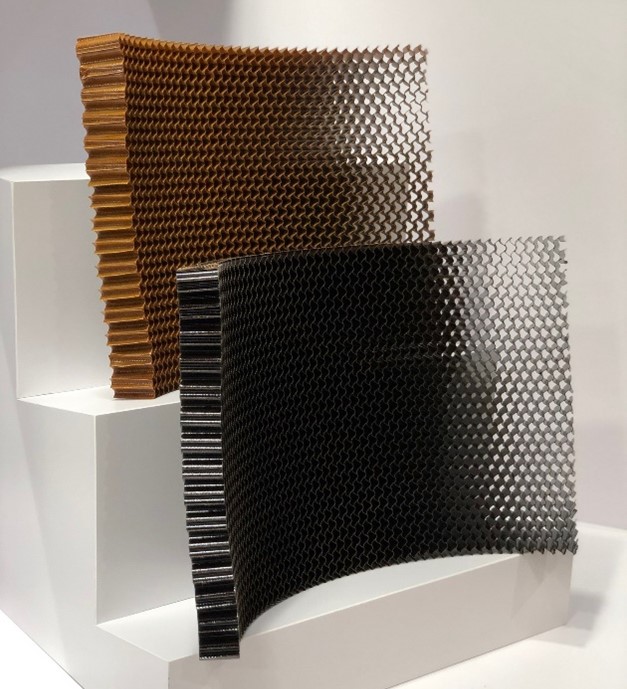

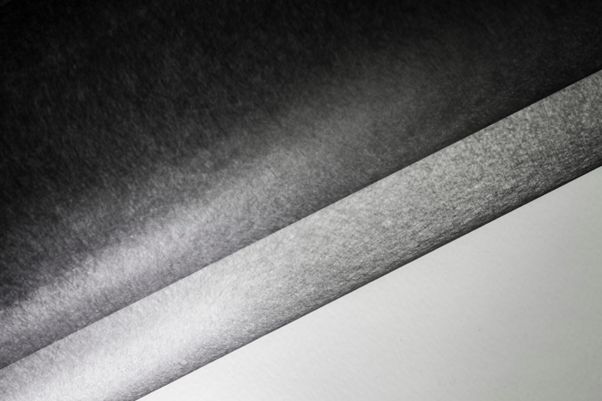

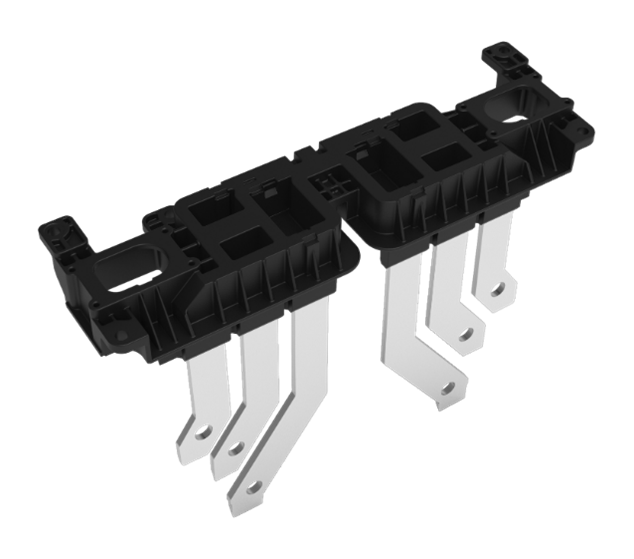

SURFACETEC streamlines composite manufacturing by enhancing surface quality, optimising resin flow, imparting functionality and reducing process complexity. Perfectly suited for industries that demand greater efficiency and cost savings, SURFACETEC will deliver transformative advantages to sectors including aerospace, automotive, sporting goods, industrial and medical.

Manufacturers often face challenges related to surface porosity, microcracking, and time-intensive finishing processes, such as sanding and painting. SURFACETEC eliminates these inefficiencies by delivering a resin-rich, high-quality surface finish that reduces the need for secondary processing. This significantly cuts down on production time and cost.

SURFACETEC also ensures superior resin flow and wet-out, ensuring faster, more consistent infusion and fewer wasted parts, leading to increased production throughput. Additionally, it is accredited to AS9100 and compatible with all major composite manufacturing techniques, ensuring a seamless adoption into existing production lines.

Beyond efficiency, SURFACETEC enhances composite functionality and performance by incorporating materials such as aramid veils for abrasion resistance and antistatic veils for electrostatic dissipation. Resulting in stronger, lighter, and longer-lasting composite components, critical for industries where material performance directly impacts operational success.

SURFACETEC also offers multiple sustainability benefits; as well as enabling the production of lighter final components to support increased fuel efficiency in applications such as aerospace and automotive, the range also incorporates nonwovens manufactured using carbon fibre reclaimed from composites. These recycled carbon surfacing veils enable manufacturers to reduce their environmental impact by providing a viable route for the reuse of fibres previously considered as waste.

“With SURFACETEC we are redefining what‘s possible in the world of composites, and especially how manufacturers should approach composite production. With shorter cycle times, lower costs, and superior performance becoming a must, companies looking to increase efficiency while maintaining high-quality standards can now integrate SURFACETEC straight into their operations.”

Realted Content

BASF launches innovative PPA for electric vehic ...

BASF announced that its newly develop ...

Read More