Australia’s ACM CRC project to develop a cost-effective and cutting-edge airframe design

Australian Composites Manufacturing Cooperative Research Centre (ACM CRC) Partners, Quickstep and RMIT University, have teamed up to develop and demonstrate an optimised sovereign Uncrewed Aircraft System (UAS) airframe design

Posted On 12 Feb 2025

Australian Composites Manufacturing Cooperative Research Centre (ACM CRC) Partners, Quickstep and RMIT University, have teamed up to develop and demonstrate an optimised sovereign Uncrewed Aircraft System (UAS) airframe design, with the knowledge and technology developed to be readily transferrable to other partners within the sovereign composites manufacturing domain. ACM CRC is a creative consortium of industry, government of Australia, and research partners.

Aircraft design today is bounded by traditional material manufacturing limitations, leading to cost overruns. Often with new technologies, such as complex airframe design with new materials, the basic manufacture processes are defined with little detail.

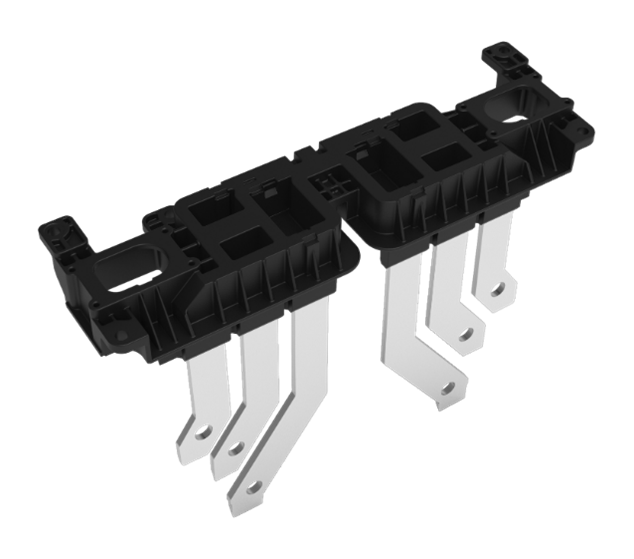

Quickstep is looking to build on its innovative AeroQure technology to design and build a highly modular composite Uncrewed Aircraft System airframe for the rapidly expanding drone delivery market, which is thought to be worth $US54 billion by 2030.

This ACM CRC project is combining advanced composite manufacturing and simulation-based design and optimisation to deliver a multi-physics simulation tool, aerodynamic and structural testing, and full-scale flight demonstration, to verify the development of a cost-effective and cutting-edge airframe design.

“Aircraft design methodology has remained relatively unchanged for many years. While there is a plethora of UAS designs in our skies today, almost all are designed for a specific mission,” said Luke Preston, Head of Technology and Partnerships at Quickstep. “The Quickstep UAS meets the requirements of a multi-mission capability by having modular aerostructure and payload configurations. It leverages a toolless, automated interface whereby a variety of payloads to suit a different missions can be identified, captured, and carried without tedious human intervention. The UAS will serve diverse use cases including bushfire fighting, tactical resupply, middle-mile logistics, and more, “he added.

The project is helping tackle key challenges in composite materials manufacturing, with a focus on intelligent manufacturing, automation, affordability, and performance. It supports the upskilling necessary for critical technology implementation and know-how, while also building analysis tools for the digital value chain. And it demonstrates design integration by enhancing design processes for digital manufacturing and technology validation of certification-ready designs of UAS composite airframes through flight testing.

“This will build upon the expertise of RMIT University in composite aerostructures, aircraft and UAS design and development, composite materials and structures testing and characterisation, multi-physics simulation, and advanced analytic tools,” said Pier Marzocca, Director of the Sir Lawrence Wackett Aerospace Research Centre at RMIT University.

It is also expected the multi-role capability, combined with the design for automated and advanced manufacturing techniques, will enable Quickstep to bring utilitarian sovereign UAS capability to the global market.

“The outputs of the research, such as cost-competitive composite materials, advanced manufacturing techniques, and multi-physics simulation capabilities, will be used to enhance the design, manufacturing, and performance optimisation of highly modular sovereign UAS,” said Dr Steve Gower, ACM CRC CEO.

“These outputs will also contribute to advancing Australian manufacturing capabilities, fostering innovation, and competing globally in the dynamic aviation technology landscape. The benefits from these outputs will reach end-users through technology transfer, licensing agreements, or direct implementation of the developed technologies in commercial UAS production,” he added.

ACM CRC is a creative consortium of industry, government of Australia, and research partners.

Realted Content

BASF launches innovative PPA for electric vehic ...

BASF announced that its newly develop ...

Read More